Altamirano A.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Talu O.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Talu O.

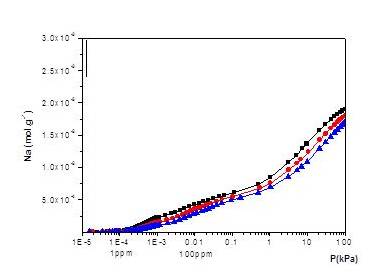

Dual-Site (Langmuir-Association Theory) model for Al-Fumarate/Water isotherms

ADSORPTION-JOURNAL OF THE INTERNATIONAL ADSORPTION SOCIETY, 2025, 31(7), p.

Dedecker K., Paret B., Presmanes L., Duployer B., Barnabe A., Menini P.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bechelany M., Drobek M., Julbe A.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bechelany M., Drobek M., Julbe A.

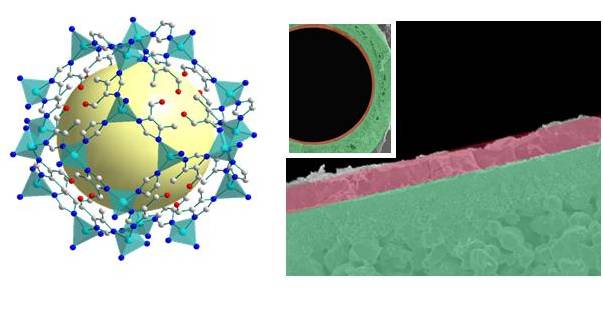

Optimizing ZIF-8 membrane growth on top of semiconductive Ga-doped ZnO sensitive layers

RSC APPLIED INTERFACES, 2025, 2(5), pp. 1345-1358

Miriam Perbet Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-125 Perbet M., Michon T.,

Miriam Perbet Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-125 Perbet M., Michon T.,  Elsje Alessandra Quadrelli Researcher 445 359 (Switchboard + 33 [0] 472 445 300) P114 Quadrelli E. A.,

Elsje Alessandra Quadrelli Researcher 445 359 (Switchboard + 33 [0] 472 445 300) P114 Quadrelli E. A.,  Mickaele Bonneau Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-214 Bonneau M.,

Mickaele Bonneau Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-214 Bonneau M.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Scalable one-step syntheses of aluminium-based MOFs

CHEMICAL COMMUNICATIONS, 2025, 61(67), pp. 12562-12565

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., De Araujo L.,

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., De Araujo L.,  Emmanuel Landrivon Personnel technique et administratif 445 384 (Standard + 33 [0] 472 445 300) P112 Landrivon E., Mello A., Radoiu M., Trillaud V., Meunier J.,

Emmanuel Landrivon Personnel technique et administratif 445 384 (Standard + 33 [0] 472 445 300) P112 Landrivon E., Mello A., Radoiu M., Trillaud V., Meunier J.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,

Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Methane pyrolysis into hydrogen and solid carbon: A comparative analysis of conventional and microwave heating approaches

CATALYSIS TODAY, 2025, 459, p.

Manokaran R.,  Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T., Eck J., Ergincan O.,

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T., Eck J., Ergincan O.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Molecular simulation of fluid adsorption in nanoporous adsorbents: simple descriptors for space decontamination applications

ADSORPTION-JOURNAL OF THE INTERNATIONAL ADSORPTION SOCIETY, 2025, 31(5), p.

De Araujo L.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Artificial intelligence-driven advances in photocatalytic hydrogen production

NEW JOURNAL OF CHEMISTRY, 2025, p.

Ho L., Lesage A., Rossini A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Dynamics Slowdown Induced by Gas Oversolubility in Nanoconfined Fluids

ACS NANO, 2025, 19(13), pp. 12971-12981

Chizallet C., Camp C.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,  Pascal Fongarland University researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Fongarland P.,

Pascal Fongarland University researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Fongarland P.,  Dorothee Laurenti Researcher 445 327 (Switchboard + 33 [0] 472 445 300) P310 Laurenti D., Lofberg A., Mauge F., Olivier-Bourbigou H.,

Dorothee Laurenti Researcher 445 327 (Switchboard + 33 [0] 472 445 300) P310 Laurenti D., Lofberg A., Mauge F., Olivier-Bourbigou H.,  Catherine Pinel Researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Pinel C., Tanchoux N.

Catherine Pinel Researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Pinel C., Tanchoux N.

Roots and Wings for a Better World at the 18th International Congress on Catalysis in Lyon, France

CHEMCATCHEM, 2025, 17(6), p.

Miriam Perbet Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-125 Perbet M.,

Miriam Perbet Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-125 Perbet M.,  Thibaud Aumond Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-208 Aumond T.,

Thibaud Aumond Student or nonpermanent staff 445 300 (Switchboard + 33 [0] 472 445 300) P-208 Aumond T.,  Corentin Collomb Student or nonpermanent staff 445 384 (Switchboard + 33 [0] 472 445 300) P-112 Collomb C.,

Corentin Collomb Student or nonpermanent staff 445 384 (Switchboard + 33 [0] 472 445 300) P-112 Collomb C.,  Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C., Imaz I., Pena G., Maspoch D., Michon T., Morales-Ospino R., Fierro V.,

Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C., Imaz I., Pena G., Maspoch D., Michon T., Morales-Ospino R., Fierro V.,  Elsje Alessandra Quadrelli Researcher 445 359 (Switchboard + 33 [0] 472 445 300) P114 Quadrelli E. A.,

Elsje Alessandra Quadrelli Researcher 445 359 (Switchboard + 33 [0] 472 445 300) P114 Quadrelli E. A.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Upscaled Al-Fumarate Synthesis and Shaping by Spray Drying

INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH, 2025, 64(12), pp. 6541-6549

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  Corentin Collomb Personnel étudiant ou non permanent 445 384 (Standard + 33 [0] 472 445 300) P-112 Collomb C., Dedecker K., Drobek M., Julbe A.,

Corentin Collomb Personnel étudiant ou non permanent 445 384 (Standard + 33 [0] 472 445 300) P-112 Collomb C., Dedecker K., Drobek M., Julbe A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Impact of ZIF flexibility for aromatic vapor capture

NEW JOURNAL OF CHEMISTRY, 2025, p.

Beucher R.,  Pavel Afanasiev Chercheur 445 466 (Standard + 33 [0] 472 445 300) P306 Afanasiev P., Lacote E.,

Pavel Afanasiev Chercheur 445 466 (Standard + 33 [0] 472 445 300) P306 Afanasiev P., Lacote E.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

The formation of cyclotriazane (N3H3) from ammonia in contact with a silver-exchanged LTA zeolite: a reliable synthesis pathway?

NEW JOURNAL OF CHEMISTRY, 2025, p.

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T., Manokaran R., Eck J., Ergincan O.,

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T., Manokaran R., Eck J., Ergincan O.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

A Review on Adsorption in Nanoporous Adsorbents for Gas Decontamination: Space Applications and Beyond

INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH, 2024, p.

Beucher R., Lacote E.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Molecular copper complexes embedded within porous polymer macroligands for the heterogeneously catalyzed aerobic oxidative formation of N-N bonds

NEW JOURNAL OF CHEMISTRY, 2024, p.

Manokaran R.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Molecular Simulation of Cyclohexane in Nanoporous Materials: Adsorption of Conformers and Coadsorption with Water and Carbon Dioxide

LANGMUIR, 2024, p.

Zuniega J., Grabulos J., Lebrun M.,  Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Brat P.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Brat P.

'Cavendish' banana crown rot control through sustained release of thymol by metal-organic frameworks (MOFs)

POSTHARVEST BIOLOGY AND TECHNOLOGY, 2024, 217, p.

Cherbanski R., Murgrabia S., Kotkowski T., Molga E., Stankiewicz A.,  Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V.,

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Towards microwave-assisted methane pyrolysis. Kinetic investigations of a Fe/C catalyst using thermogravimetric analysis coupled with gas chromatography

CHEMICAL ENGINEERING AND PROCESSING-PROCESS INTENSIFICATION, 2024, 203, p.

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., De Araujo L.,

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., De Araujo L.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,

Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Direct biogas reforming to turquoise H2 and carbon material in a catalytic fluidised-bed reactor

NEW JOURNAL OF CHEMISTRY, 2024, p.

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., Guillemot J., Beucher R., Michon T., Bonnet D.,

Valentin L'Hospital Personnel étudiant ou non permanent 445 486 (Standard + 33 [0] 472 445 300) P-127 L'Hospital V., Guillemot J., Beucher R., Michon T., Bonnet D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Oxidative coupling of biogas to ethylene over a trilobe-shaped Mn-Na2WO4/α-Al2O3 catalyst in a single-pellet reactor

APPLIED CATALYSIS A-GENERAL, 2023, 666, p.

Zuniega J., Grabulos J., Lebrun M.,  Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,

Thibaud Aumond Personnel étudiant ou non permanent 445 300 (Standard + 33 [0] 472 445 300) P-208 Aumond T.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Brat P.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Brat P.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Encapsulation of thymol and limonene in metal-organic frameworks for inhibition of Colletotrichum musae growth

INTERNATIONAL JOURNAL OF FOOD SCIENCE AND TECHNOLOGY, 2023, p.

Rivet Q., Beucher R.,  Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F., Nardin T.,

Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F., Nardin T.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Quantification of relevant Bronsted acid sites on Cl-doped alumina catalysts for the isomerization of olefins

JOURNAL OF CATALYSIS, 2023, 427, p.

Huve J.,  Frederic Bourgain Personnel technique et administratif 445 363 (Standard + 33 [0] 472 445 300) P21 Bourgain F.,

Frederic Bourgain Personnel technique et administratif 445 363 (Standard + 33 [0] 472 445 300) P21 Bourgain F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Millet J. M. M.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Millet J. M. M.

Development of a cell for in-situ/operando Mössbauer spectroscopy studies of Catalysts: Application to the characterization of iron nanoparticles used in Fischer-Tropsch reaction

REVIEW OF SCIENTIFIC INSTRUMENTS, 2023, 94(9), p.

Millet A., Courtney C., Gossard A., Couchaux G.,  Pascale Mascunan Personnel technique et administratif 445 311 (Standard + 33 [0] 472 445 300) P411 Mascunan P.,

Pascale Mascunan Personnel technique et administratif 445 311 (Standard + 33 [0] 472 445 300) P411 Mascunan P.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Desilicated ZSM-5 zeolites for optimized xenon adsorption at very low pressure

MICROPOROUS AND MESOPOROUS MATERIALS, 2023, 360, p.

Bredy P.,  Ludovic Fine Personnel technique et administratif 445 851 (Standard + 33 [0] 472 445 300) C14.008 Fine L.,

Ludovic Fine Personnel technique et administratif 445 851 (Standard + 33 [0] 472 445 300) C14.008 Fine L.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Evolution of sample optical pathlength during diffuse reflectance FT-IR analyses

CATALYSIS TODAY, 2023, 424, p.

Cardenas C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.

Modeling of Water Vapor Adsorption and Desorption in an Industrial Medical Air Dryer

INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH, 2023, 62(31), pp. 12315-12328

Courtney C., Millet A., Couchaux G., Gossard A.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  Nicolas Bonnet Personnel technique et administratif 445 361 (Standard + 33 [0] 472 445 300) P420 Bonnet N., Topin S.,

Nicolas Bonnet Personnel technique et administratif 445 361 (Standard + 33 [0] 472 445 300) P420 Bonnet N., Topin S.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

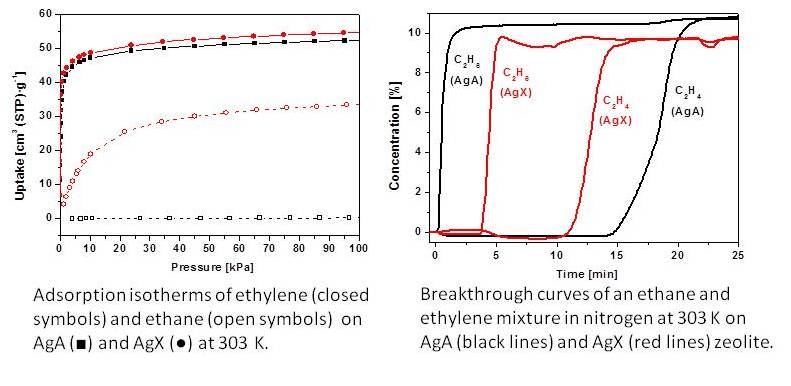

Toward Optimal Xenon Adsorption Capacity at Low Pressure on Silver-Exchanged Zeolites

INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH, 2023, 62(30), pp. 11939-11947

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.

Investigating the reaction mechanism of dimethyl carbonate synthesis through isotopic labeling experiments

CATALYSIS COMMUNICATIONS, 2023, 179, p.

Ursueguia D.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  Corentin Collomb Personnel étudiant ou non permanent 445 384 (Standard + 33 [0] 472 445 300) P-112 Collomb C., Cardenas C.,

Corentin Collomb Personnel étudiant ou non permanent 445 384 (Standard + 33 [0] 472 445 300) P-112 Collomb C., Cardenas C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Diaz E., Ordonez S.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Diaz E., Ordonez S.

Evaluation of HKUST-1 as Volatile Organic Compound Adsorbents for Respiratory Filters

LANGMUIR, 2022, p.

Cardenas C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Aubry R.

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Aubry R.

Modeling of equilibrium water vapor adsorption isotherms on activated carbon, alumina and hopcalite

FLUID PHASE EQUILIBRIA, 2022, 561, p.

Bredy P.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

On the link between CO surface coverage and selectivity to CH4 during CO2 hydrogenation over supported cobalt catalysts

JOURNAL OF CATALYSIS, 2022, 411, pp. 93-96

Pagis C., Laprune D., Roiban L.,  Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T.,

Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T.,  Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C.,  Alain Tuel Researcher 445 395 (Switchboard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Researcher 445 395 (Switchboard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Morphology and topology assessment in hierarchical zeolite materials: adsorption hysteresis, scanning behavior, and domain theory

INORGANIC CHEMISTRY FRONTIERS, 2022, 9(12), pp. 2903-2916

Rivet Q., Meyet J., Rivallan M., Nardin T.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Characterization of the Bronsted acidity of PtSn/Al2O3 surfaces by adsorption of 2,6-di-tert-butylpyridine

NEW JOURNAL OF CHEMISTRY, 2022, 46(16), pp. 7557-7562

Ghosh A., Legrand A., Rajapaksha R., Craig G., Sassoye C., Balazs G.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Furukawa S.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Furukawa S.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Wisser F.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Wisser F.

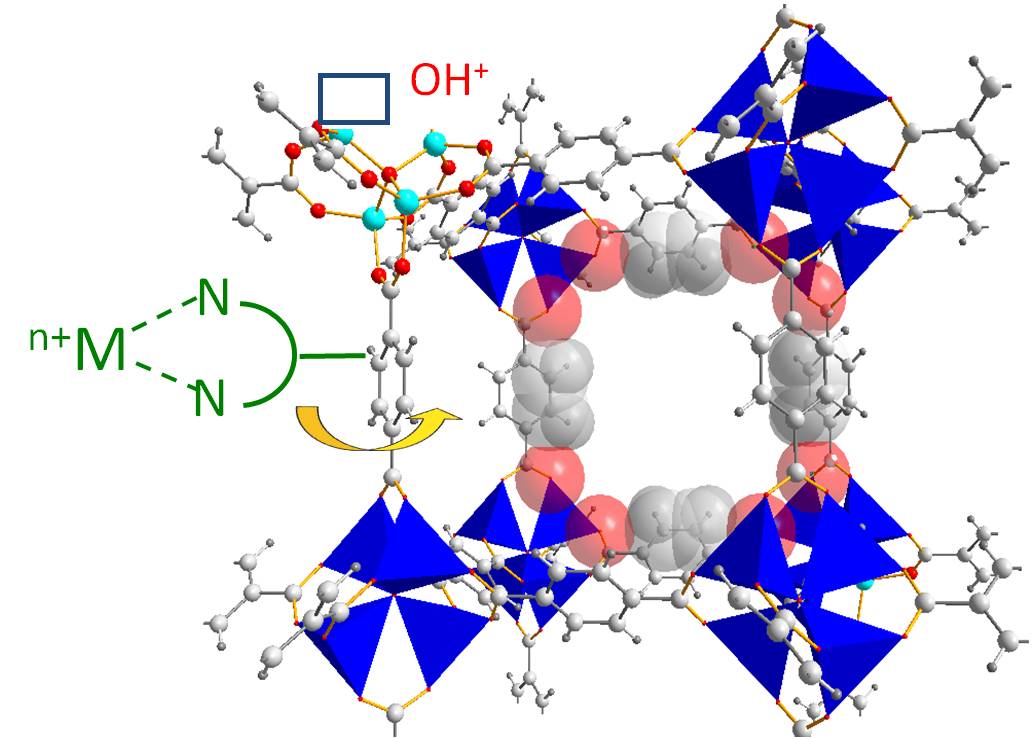

Rhodium-Based Metal-Organic Polyhedra Assemblies for Selective CO2 Photoreduction

JOURNAL OF THE AMERICAN CHEMICAL SOCIETY, 2022, 144(8), pp. 3626-3636

Lions M.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Coasne B.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Coasne B.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

The Pivotal Role of Critical Hydroxyl Concentration in Si-Rich Zeolites for Switching Vapor Adsorption

JOURNAL OF PHYSICAL CHEMISTRY C, 2021, 125(41), pp. 22890-22897

Chapelliere Y.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.

Kinetics of n-Hexane Cracking over Mesoporous HY Zeolites Based on Catalyst Descriptors

CATALYSTS, 2021, 11(6), p.

Said-Aizpuru O., Allain F., Dandeu A., Diehl F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Joly J.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Joly J.

Kinetic modelling of Pt/gamma-Al2O3-Cl catalysts formulation changes in n-heptane reforming

REACTION CHEMISTRY & ENGINEERING, 2021, 6(6), pp. 1079-1091

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Surface effect of nano-sized cerium-zirconium oxides for the catalytic conversion of methanol and CO2 into dimethyl carbonate

JOURNAL OF CATALYSIS, 2021, 394, pp. 486-494

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Hamill C., Casaban J., Didriksen T., Blom R., Velte A., Fueldner G., Gantenbein P., Persdorf P., Daguenet-Frick X.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Hamill C., Casaban J., Didriksen T., Blom R., Velte A., Fueldner G., Gantenbein P., Persdorf P., Daguenet-Frick X.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Adsorber heat exchanger using Al-fumarate beads for heat-pump applications - a transport study

FARADAY DISCUSSIONS, 2021, 225, pp. 384-402

Morgado Prates A.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Pagis C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Pagis C.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Faster transport in hollow zeolites

Microporous and Mesoporous Materials, 2020, 308, p. 110499

Wisser F., Duguet M., Perrinet Q., Ghosh A., Alves-Favaro M., Mohr Y.,  Chantal Lorentz Technical and administrative staff 445 339 (Switchboard + 33 [0] 472 445 300) P206 Lorentz C., Quadrelli E., Palkovits R.,

Chantal Lorentz Technical and administrative staff 445 339 (Switchboard + 33 [0] 472 445 300) P206 Lorentz C., Quadrelli E., Palkovits R.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Mellot-Draznieks C., De Waele V.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Mellot-Draznieks C., De Waele V.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Molecular Porous Photosystems Tailored for Long-Term Photocatalytic CO2 Reduction

Angewandte chemie-international edition, 2020, 59, pp. 5116-5122

Said-Aizpuru O., Allain F., Diehl F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Joly J., Dandeu A.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Joly J., Dandeu A.

A naphtha reforming process development methodology based on the identification of catalytic reactivity descriptors

New journal of chemistry, 2020, 44, pp. 7243-7260

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Discovery of very active catalysts for methanol carboxylation into DMC by screening of a large and diverse catalyst library

New journal of chemistry, 2020, 44, pp. 6312-6320

Said-Aizpuru O., Batista A., Bouchy C., Petrazzuoli V., Allain F., Diehl F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F., Joly J., Dandeu A.

Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F., Joly J., Dandeu A.

Non Monotonous Product Distribution Dependence on Pt/gamma-Al2O3-Cl Catalysts Formulation in n-Heptane Reforming.

Chemcatchem, 2020, 8, pp. 2262-2270

Prates A., Chetot T., Burel L., Pagis C., Martinez-Franco R., Dodin M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Hollow structures by controlled desilication of beta zeolite nanocrystals

Journal of solid state chemistry, 2020, 281, p. 121033

Coasne B.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Gas oversolubility in nanoconfined liquids: Review and perspectives for adsorbent design

Microporous and mesoporous materials, 2019, 288, p.

Monpezat A., Topin S., Thomas V., Pagis C.,  Mimoun Aouine Technical and administrative staff 445 372 (Switchboard + 33 [0] 472 445 300) P106 Aouine M., Burel L.,

Mimoun Aouine Technical and administrative staff 445 372 (Switchboard + 33 [0] 472 445 300) P106 Aouine M., Burel L.,  Luis Cardenas Researcher 445 314 (Switchboard + 33 [0] 472 445 300) P205 Cardenas L.,

Luis Cardenas Researcher 445 314 (Switchboard + 33 [0] 472 445 300) P205 Cardenas L.,  Alain Tuel Researcher 445 395 (Switchboard + 33 [0] 472 445 300) P408 Tuel A., Malchere A.,

Alain Tuel Researcher 445 395 (Switchboard + 33 [0] 472 445 300) P408 Tuel A., Malchere A.,  Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T.,

Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Roiban L.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Roiban L.

Migration and Growth of Silver Nanoparticles in Zeolite Socony Mobil 5 (ZSM-5) Observed by Environmental Electron Microscopy: Implications for Heterogeneous Catalysis

Acs applied nano materials, 2019, 2, pp. 6452-6461

Coasne B.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Gas oversolubility in nanoconfined liquids: Review and perspectives for adsorbent design

Microporous and mesoporous materials, 2019, 288, p.

Monpezat A., Couchaux G., Thomas V., Artheix A., Deliere L., Greau C., Topin S., Coasne B., Roiban L.,  Luis Cardenas Chercheur 445 314 (Standard + 33 [0] 472 445 300) P205 Cardenas L.,

Luis Cardenas Chercheur 445 314 (Standard + 33 [0] 472 445 300) P205 Cardenas L.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Effect of Chlorine-Containing VOCs on Silver Migration and Sintering in ZSM-5 Used in a TSA Process

Catalysts, 2019, 9, p.

Bueno A., Mayer M., Weber M., Bechelany M., Klotz M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Impregnation Protocols on Alumina Beads for Controlling the Preparation of Supported Metal Catalysts

Catalysts, 2019, 9, p.

Pizzoccaro-Zilamy M., Pina S., Rebiere B.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Drobek M., Silly G., Julbe A., Guerrero G.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Drobek M., Silly G., Julbe A., Guerrero G.

Controlled grafting of dialkylphosphonate-based ionic liquids on gamma-alumina: design of hybrid materials with high potential for CO2 separation applications

Rsc advances, 2019, 9, pp. 19882-19894

Pagis C., Bouchy C., Dodin M., Franco R.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Hollow Y zeolite single crystals: synthesis, characterization and activity in the hydroisomerization of n-hexadecane

Oil & gas science and technology-revue d ifp energies nouvelles, 2019, 74, p.

Monpezat A., Topin S., Deliere L.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Evaluation Methods of Adsorbents for Air Purification and Gas Separation at Low Concentration: Case Studies on Xenon and Krypton

Industrial & engineering chemistry research, 2019, 58, pp. 4560-4571

Prates A.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Dodin M., Franco R.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Dodin M., Franco R.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Hydrogenation Size-Selective Pt/Hollow Beta Catalysts

Chemistry-a european journal, 2019, 25, pp. 2972-2977

Xu H., Chen B., Tan P., Xuan J., Maroto-Valer M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Sun Q., Ni M.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Sun Q., Ni M.

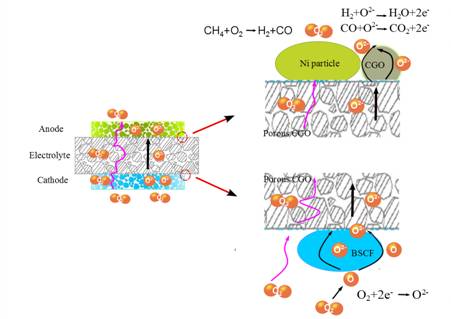

Modeling of all-porous solid oxide fuel cells with a focus on the electrolyte porosity design

Applied energy, 2019, 235, pp. 602-611

Pagis C.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Dodin M., Martinez-Franco R.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Dodin M., Martinez-Franco R.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Demonstration of Improved Effectiveness Factor of Catalysts Based on Hollow Single Crystal Zeolites

Chemcatchem, 2018, 10, pp. 4525-4529

Khabzina Y., Laroche C., Perez-Pellitero J.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Quantitative structure-property relationship approach to predicting xylene separation with diverse exchanged faujasites

Physical chemistry chemical physics, 2018, 20, pp. 23773-23782

Pagis C., Vennerie A., Prates A., Bats N.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Hollow polycrystalline Y zeolite shells obtained from selective desilication of Beta-Y core-shell composites

Microporous and mesoporous materials, 2018, 265, pp. 123-131

Khabzina Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Unravelling ammonia adsorption mechanisms of adsorbents in humid conditions

Microporous and mesoporous materials, 2018, 265, pp. 143-148

Khabzina Y., Dhainaut J., Ahlhelm M., Richter H., Reinsch H., Stock N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Synthesis and Shaping Scale-up Study of Functionalized UiO-66 MOF for Ammonia Air Purification Filters

Industrial & engineering chemistry research, 2018, 57, pp. 8200-8208

Xu H., Chen B., Tan P., Cai W., He W.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Ni M.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Ni M.

Modeling of all porous solid oxide fuel cells

Applied energy, 2018, 219, pp. 105-113

Ramos-Fernandez E., Grau-Atienza A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Aguado S.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Aguado S.

A water-based room temperature synthesis of ZIF-93 for CO2 adsorption

Journal of materials chemistry a, 2018, 6, pp. 5598-5602

Wisser F., Mohr Y., Quadrelli E.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Microporous Polymers as Macroligands for Pentamethylcyclopentadienylrhodium Transfer-Hydrogenation Catalysts

Chemcatchem, 2018, 10, pp. 1778-1782

Pagis C., Prates A., Bats N.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

High-silica hollow Y zeolite by selective desilication of dealuminated NaY crystals in the presence of protective Al species

Crystengcomm, 2018, 20, pp. 1564-1572

Wisser F., Berruyer P.,  Luis Cardenas Researcher 445 314 (Switchboard + 33 [0] 472 445 300) P205 Cardenas L., Mohr Y., Quadrelli E., Lesage A.,

Luis Cardenas Researcher 445 314 (Switchboard + 33 [0] 472 445 300) P205 Cardenas L., Mohr Y., Quadrelli E., Lesage A.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.

Hammett Parameter in Microporous Solids as Macroligands for Heterogenized Photocatalysts

Acs catalysis, 2018, 8, pp. 1653-1661

Avci-Camur C., Troyano J., Perez-Carvajal J., Legrand A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Imaz I., Maspoch D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Imaz I., Maspoch D.

Aqueous production of spherical Zr-MOF beads via continuous-flow spray-drying

Green chemistry, 2018, 20, pp. 873-878

Prates A., Pagis C.,  Frederic Meunier Researcher 445 468 (Switchboard + 33 [0] 472 445 300) C13.009 Meunier F., Burel L.,

Frederic Meunier Researcher 445 468 (Switchboard + 33 [0] 472 445 300) C13.009 Meunier F., Burel L.,  Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T., Roiban L., Koneti S., Bats N.,

Thierry Epicier Emeritus researcher 445 300 (Switchboard + 33 [0] 472 445 300) P-106 Epicier T., Roiban L., Koneti S., Bats N.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Tuelt A.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Tuelt A.

Hollow Beta Zeolite Single Crystals for the Design of Selective Catalysts

Crystal growth & design, 2018, 18, pp. 592-596

Laprune D.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Pieterse J., Steele A., Thorpe S.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F., Pieterse J., Steele A., Thorpe S.

Effects of H2S and phenanthrene on the activity of Ni and Rh-based catalysts for the reforming of a simulated biomass-derived producer gas

Applied catalysis b-environmental, 2018, 221, pp. 206-214

Roiban L., Li S.,  Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M.,

Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Epicier T.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Epicier T.

Fast ‘ Operando ’ electron nanotomography

Journal of microscopy, 2017, p.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Lysenko V, Lehtinen J, Legrand A, Wisser F, Quadrelli E,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Lysenko V, Lehtinen J, Legrand A, Wisser F, Quadrelli E,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Sensitive Photoacoustic IR Spectroscopy for the Characterization of Amino/Azido Mixed-Linker Metal-Organic Frameworks

Chemphyschem, 2017, 18, pp. 2855-2858

Laprune D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Highly Dispersed Nickel Particles Encapsulated in Multi-hollow Silicalite-1 Single Crystal Nanoboxes: Effects of Siliceous Deposits and Phosphorous Species on the Catalytic Performances

CHEMCATCHEM, 2017, 9, pp. 2297-2307

Khabzina Y., Laroche C., Perez-Pellitero J.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Xylene separation on a diverse library of exchanged faujasite zeolites

Microporous and Mesoporous Materials, 2017, 247, pp. 52-59

Khabzina Y., Laroche C., Pagis C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Monovalent and bivalent cations exchange isotherms for faujasites X and Y

Physical Chemistry Chemical Physics, 2017, 19, pp. 17242-17249

Dhainaut J., Avci-Camur C., Troyano J., Legrand A.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Imaz I., Maspoch D., Reinsch H.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Imaz I., Maspoch D., Reinsch H.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Systematic study of the impact of MOF densification into tablets on textural and mechanical properties

CrystEngComm, 2017, 19, pp. 4211-4218

Laprune D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Selective removal of external Ni nanoparticles on Ni@silicalite-1 single crystal nanoboxes: Application to size-selective arene hydrogenation

Applied Catalysis A : General, 2017, 535, pp. 69-76

Laprune D., Theodoridi C.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Effect of polyaromatic tars on the activity for methane steam reforming of nickel particles embedded in silicalite-1

Applied Catalysis B: Environmental, 2017, 204, pp. 515-524

Deliere L., Coasne B., Topin S., Greau C., Moulin C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Breakthrough in Xenon Capture and Purification Using Adsorbent-Supported Silver Nanoparticles

Chemistry-a european journal, 2016, 22, pp. 9660-9666

Todorova T. K., Rozanska X., Gervais C., Legrand A., Ho L. N., Berruyer P., Lesage A., Emsley L.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Mellot-Draznieks C.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Mellot-Draznieks C.

Molecular Level Characterization of the Structure and Interactions in Peptide-Functionalized Metal-Organic Frameworks

Chemistry - A European Journal, 2016, 22, pp. 16531-16538

Pagis C., Prates A. R. M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bats N.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bats N.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Hollow Zeolite Structures: An Overview of Synthesis Methods

Chemistry of Materials, 2016, 28, pp. 5205-5223

Li S.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Rousset J. L.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Rousset J. L.,  Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F.,

Franck Morfin Personnel technique et administratif 445 331 (Standard + 33 [0] 472 445 300) P406 Morfin F.,  Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M., Burel L.,

Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M., Burel L.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Hollow Zeolite Single-Crystals Encapsulated Alloy Nanoparticles with Controlled Size and Composition

Chemnanomat, 2016, 2, pp. 534-539

Legrand A., Pastushenko A., Lysenko V., Geloen A., Quadrelli E. A.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Enhanced Ligand-Based Luminescence in Metal-Organic Framework Sensor

Chemnanomat, 2016, 2, pp. 866-872

Deliere L., Villemot F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Galarneau A., Topin S., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Galarneau A., Topin S., Coasne B.

Adsorption in heterogeneous porous media: Hierarchical and composite solids.

Microporous and Mesoporous Materials, 2016, 229, pp. 145-154

Novruzova N.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.

Influence of crystal size on the uptake rate of isooctane in plain and hollow silicalite-1 crystals

Microporous and Mesoporous Materials, 2016, 228, pp. 147-152

Aguado S., El-Jamal S.,  Frederic Meunier Researcher 445 468 (Switchboard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Researcher 445 468 (Switchboard + 33 [0] 472 445 300) C13.009 Meunier F.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

A Pt/Al2O3-supported metal-organic framework film as the size-selective core-shell hydrogenation catalyst

Chemical Communications, 2016, 52, pp. 7161-7163

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.

Perspectives on zeolite-encapsulated metal nanoparticles and their applications in catalysis

New Journal of Chemistry, 2016, p.

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Vandichel M.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Vandichel M.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Origin of highly active metal-organic framework catalysts: defects? Defects!

Dalton transactions (Cambridge, England : 2003), 2016, 45, pp. 4090-9

Li S.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,  Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M.,

Mimoun Aouine Personnel technique et administratif 445 372 (Standard + 33 [0] 472 445 300) P106 Aouine M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Platinum nanoparticles entrapped in zeolite nanoshells as active and sintering-resistant arene hydrogenation catalysts

Journal of Catalysis, 2015, 332, pp. 25-30

Linh Ngoc Ho,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Solubility of Gases in Water Confined in Nanoporous Materials: ZSM-5, MCM-41, and MIL-100

Journal of Physical Chemistry C, 2015, p.

Bonnefoy J., Legrand A., Quadrelli E. A.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Enantiopure Peptide-Functionalized Metal-Organic Frameworks

Journal of the American Chemical Society, 2015, 137, pp. 9409-9416

Baias M., Lesage A., Aguado S.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Moizan-Baslé V., Audebrand N.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Moizan-Baslé V., Audebrand N.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Emsley L.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Emsley L.

Superstructure of a Substituted Zeolitic Imidazolate Metal–Organic Framework Determined by Combining Proton Solid-State NMR Spectroscopy and DFT Calculations

Angewandte Chemie International Edition, 2015, 54, pp. 5971--5976

Guo Y., Largiller G., Guizard C., Tardivat C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

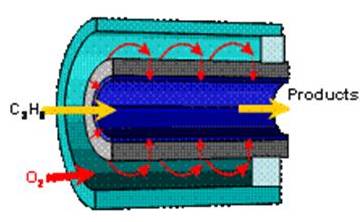

Coke-free operation of an all porous solid oxide fuel cell (AP-SOFC) used as an O-2 supply device

Journal of Materials Chemistry. A, 2015, 3, pp. 2684-2689

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Proline-functionalized metal-organic frameworks and their use in asymmetric catalysis: pitfalls in the MOFs rush

RSC Advances, 2015, 5, pp. 11254-11256

Rochoux M., Guo Y.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Determination of oxygen adsorption-desorption rates and diffusion rate coefficients in perovskites at different oxygen partial pressures by a microkinetic approach

Physical Chemistry Chemical Physics, 2015, 17, pp. 1469-1481

Li S.,  Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Laprune D.,

Alain Tuel Chercheur 445 395 (Standard + 33 [0] 472 445 300) P408 Tuel A., Laprune D.,  Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,

Frederic Meunier Chercheur 445 468 (Standard + 33 [0] 472 445 300) C13.009 Meunier F.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Transition-Metal Nanoparticles in Hollow Zeolite Single Crystals as Bifunctional and Size-Selective Hydrogenation Catalysts

Chemistry of Materials, 2015, 27, pp. 276-282

Chambers M. B., Wang X., Elgrishi N., Hendon C. H., Walsh A., Bonnefoy J.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Quadrelli E. A.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Quadrelli E. A.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Mellot-Draznieks C., Fontecave M.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D., Mellot-Draznieks C., Fontecave M.

Photocatalytic Carbon Dioxide Reduction with Rhodium-based Catalysts in Solution and Heterogenized within Metal-Organic Frameworks

Chemsuschem, 2015, 8, pp. 603-608

Morra G.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bouchy C., Morin S.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Bouchy C., Morin S.

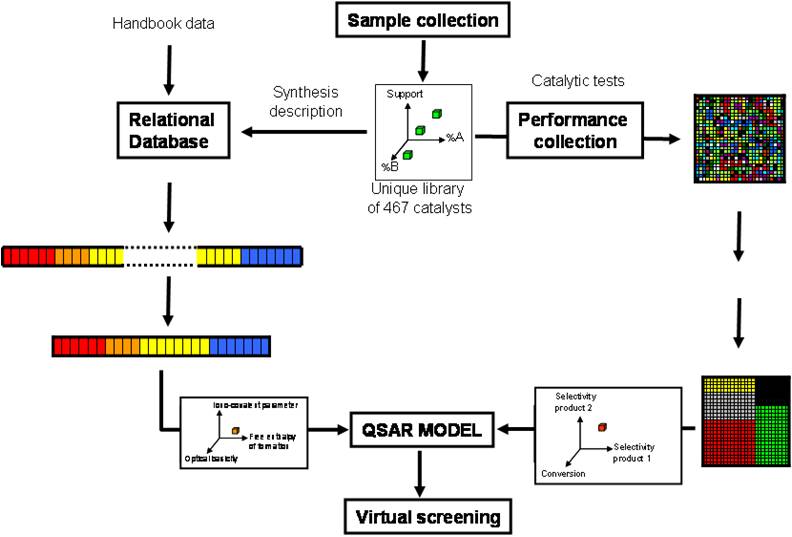

Knowledge Based Catalyst Design by High Throughput Screening of Model Reactions and Statistical Modelling

Oil and Gas Science and Technology, 2013, 68, pp. 487-504

Guo Y., Bessaa M., Aguado S., Steil M. C., Rembelski D., Rieu M., Viricelle J. -P., Benameur N., Guizard C., Tardivat C.,  Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,

Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

An all porous solid oxide fuel cell (SOFC): a bridging technology between dual and single chamber SOFCs

European Energy and Environmental Science, 2013, 6, pp. 2119-2123

Ho L. N., Clauzier S.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Coasne B.

Gas Uptake in Solvents Confined in Mesopores: Adsorption versus Enhanced Solubility

Journal of Physical Chemistry Letters, 2013, 4, pp. 2274-2278

Sublet J., Pera-Titus M.,  Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,

Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Schrive L., Chanaud P., Siret B., Durécu S.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Schrive L., Chanaud P., Siret B., Durécu S.

Technico-economical assessment of MFI-type zeolite membranes for CO2 capture from post-combustion flue gases

AIChE Journal, 2012, 58, pp. 3183-3194

Lescouet T., Kockrick E., Bergeret G., Pera-Titus M., Aguado S.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Homogeneity of flexible metal-organic frameworks containing mixed linkers

Journal of Materials Chemistry, 2012, 22, pp. 10287-10293

Savonnet M., Camarata A.,  Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Bazer-Bachi D., Bats N., Lecocq V.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Bazer-Bachi D., Bats N., Lecocq V.,  Catherine Pinel Researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Pinel C.,

Catherine Pinel Researcher 445 478 (Switchboard + 33 [0] 472 445 300) P201 Pinel C.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Tailoring metal-organic framework catalysts by click chemistry

Dalton Transactions, 2012, 41, pp. 3945-3948

Rossini A. J., Zagdoun A., Lelli M.,  Jerome Canivet Chercheur 445 424 (Standard + 33 [0] 472 445 300) P105 Canivet J., Aguado S., Ouari O., Tordo P., Rosay M., Maas W. E., Coperet C.,

Jerome Canivet Chercheur 445 424 (Standard + 33 [0] 472 445 300) P105 Canivet J., Aguado S., Ouari O., Tordo P., Rosay M., Maas W. E., Coperet C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Emsley L., Lesage A.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Emsley L., Lesage A.

Dynamic Nuclear Polarization Enhanced Solid-State NMR Spectroscopy of Functionalized Metal-Organic Frameworks

Angewandte Chemie International Edition, 2012, 51, pp. 123-127

Savonnet M., Kockrick E., Camarata A., Bazer-Bachi D., Bats N., Lecocq V.,  Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,

Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Combinatorial synthesis of metal-organic frameworks libraries by click-chemistry

New Journal of Chemistry, 2011, 35, pp. 1892-1897

Lescouet T., Kockrick E., Bergeret G., Pera-Titus M.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Engineering MIL-53(Al) flexibility by controlling amino tags

Dalton Transactions, 2011, 40, pp. 11359-11361

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Aguado S., Bergeret G.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Aguado S., Bergeret G.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Amino acid functionalized metal-organic frameworks by a soft coupling-deprotection sequence

Chemical Communications, 2011, 47, pp. 11650-11652

Bassou B.,  Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N., Iojoiu E. E.,

Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N., Iojoiu E. E.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Lombaert K., Bianchi D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Lombaert K., Bianchi D.,  Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C.

Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C.

High-throughput approach to the catalytic combustion of diesel soot II: Screening of oxide-based catalysts

Catalysis Today, 2011, 159, pp. 138-143

Aguado S.,  Jerome Canivet Chercheur 445 424 (Standard + 33 [0] 472 445 300) P105 Canivet J.,

Jerome Canivet Chercheur 445 424 (Standard + 33 [0] 472 445 300) P105 Canivet J.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Tuning the activity by controlling the wettability of MOF eggshell catalysts: A quantitative structure-activity study

Journal of Catalysis, 2011, 284, pp. 207-214

Kockrick E., Lescouet T., Kudrik E. V., Sorokin A. B.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Synergistic effects of encapsulated phthalocyanine complexes in MIL-101 for the selective aerobic oxidation of tetralin

Chemical Communications, 2011, 47, pp. 1562-1564

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Aguado S.,

Jerome Canivet Researcher 445 424 (Switchboard + 33 [0] 472 445 300) P105 Canivet J., Aguado S.,  Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C.,

Cecile Daniel Technical and administrative staff 445 365 (Switchboard + 33 [0] 472 445 300) P109 Daniel C.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Engineering the Environment of a Catalytic Metal-Organic Framework by Postsynthetic Hydrophobization

ChemCatChem, 2011, 3, pp. 675-678

Aguado S., Bergeret G., Titus M. P., Moizan V., Nieto-Draghi C., Bats N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Guest-induced gate-opening of a zeolite imidazolate framework

New Journal of Chemistry, 2011, 35, pp. 546-550

Aguado S., Nicolas C. H., Moizan-Basle V., Nieto C., Amrouche H., Bats N., Audebrand N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Facile synthesis of an ultramicroporous MOF tubular membrane with selectivity towards CO2

New Journal of Chemistry, 2011, 35, pp. 41-44

Anne Giroir-Fendler Enseignant-chercheur 431 586 (Standard + 33 [0] 472 445 300) C15.007 Giroir-Fendler A.,

Anne Giroir-Fendler Enseignant-chercheur 431 586 (Standard + 33 [0] 472 445 300) C15.007 Giroir-Fendler A.,  Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N., Dalmon J. A.,

Nolven Guilhaume Chercheur 445 389 (Standard + 33 [0] 472 445 300) P107 Guilhaume N., Dalmon J. A.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Pera-Titus M.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Pera-Titus M.

Dr. Sylvain Miachon (1967-2009) Preface

Catalysis Today, 2010, 156, p. 75

Jacquens J.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Georges S., Viricelle J. -P., Gaudillere C., Gwenael C., Lacorre P.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Georges S., Viricelle J. -P., Gaudillere C., Gwenael C., Lacorre P.

Tests for the Use of La2Mo2O9-based Oxides as Multipurpose SOFC Core Materials

Fuel Cells, 2010, 10, pp. 433-439

Gaudillere C.,  Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,

Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,  Claude Mirodatos Emeritus researcher 445 366 (Switchboard + 33 [0] 472 445 300) P114 Mirodatos C., Caboche G.,

Claude Mirodatos Emeritus researcher 445 366 (Switchboard + 33 [0] 472 445 300) P114 Mirodatos C., Caboche G.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Screening of ceria-based catalysts for internal methane reforming in low temperature SOFC

Catalysis Today, 2010, 157, pp. 263-269

Ravon U., Chaplais G., Chizallet C., Seyyedi B., Bonino F., Bordiga S., Bats N.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Investigation of Acid Centers in MIL-53(Al, Ga) for Bronsted-Type Catalysis: In Situ FTIR and Ab Initio Molecular Modeling

ChemCatChem, 2010, 2, pp. 1235-1238

Gaudillere C.,  Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,

Philippe Vernoux Researcher 431 587 (Switchboard + 33 [0] 472 445 300) C15.009 Vernoux P.,  David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Researcher 445 365 (Switchboard + 33 [0] 472 445 300) P109 Farrusseng D.

Impact of reforming catalyst on the anodic polarisation resistance in single-chamber SOFC fed by methane

Electrochemistry Communications, 2010, 12, pp. 1322-1325

Savonnet M., Bazer-Bachi D., Bats N., Perez-Pellitero J., Jeanneau E., Lecocq V.,  Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,

Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Generic Postfunctionalization Route from Amino-Derived Metal-Organic Frameworks

Journal of the American Chemical Society, 2010, 132, p. 4518

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Clerc F.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Clerc F.,  Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C., Rakotomalala R.

Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C., Rakotomalala R.

Virtual screening of materials using neuro-genetic approach: Concepts and implementation

Computational Materials Science, 2009, 45, pp. 52-59

Savonnet M., Aguado S., Ravon U., Bazer-Bachi D., Lecocq V., Bats N.,  Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,

Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.

Solvent free base catalysis and transesterifiation over basic functionalised Metal-Organic Frameworks

Green Chemistry, 2009, 11, pp. 1729-1732

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Gaudillere C., Ravon U.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Gaudillere C., Ravon U.,  Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,

Yves Schuurman Chercheur 445 482 (Standard + 33 [0] 472 445 300) P129 Schuurman Y.,  Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C., Dubbeldam D., Frost H., Snurr R. Q.

Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C., Dubbeldam D., Frost H., Snurr R. Q.

Heats of Adsorption for Seven Gases in Three Metal-Organic Frameworks: Systematic Comparison of Experiment and Simulation

Langmuir, 2009, 25, pp. 7383-7388

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Aguado S.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Aguado S.,  Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.

Catherine Pinel Chercheur 445 478 (Standard + 33 [0] 472 445 300) P201 Pinel C.

Metal-Organic Frameworks: Opportunities for Catalysis

Angewandte Chemie-International Edition, 2009, 48, pp. 7502-7513

Morra G., Desmartin-Chomel A.,  Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Ravon U.,

Cecile Daniel Personnel technique et administratif 445 365 (Standard + 33 [0] 472 445 300) P109 Daniel C., Ravon U.,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Cowan R., Krusche A.,

David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Cowan R., Krusche A.,  Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C.

Claude Mirodatos Chercheur émérite 445 366 (Standard + 33 [0] 472 445 300) P114 Mirodatos C.

High-throughput gas phase transient reactor for catalytic material characterization and kinetic studies

Chemical Engineering Journal, 2008, 138, pp. 379-388

Schuth F, Baumes L, Clerc F, Demuth D,  David Farrusseng Chercheur 445 365 (Standard + 33 [0] 472 445 300) P109 Farrusseng D., Llamas-Galilea J, Klanner C, Klein J, Martinez-Joaristi A, Procelewska J, Saupe M, Schunk S, Schwickardi M, Strehlau W, Zech T