Our group develops materials and processes together in a concerted manner, from proof of concept to lab scale demonstrator.

Our skills cover a wide range of topics and expertise in Chemistry, Material Science, Chemical Engineering and Analytics allowing to address current technical and scientific challenges in

Heterogeneous Catalysis.

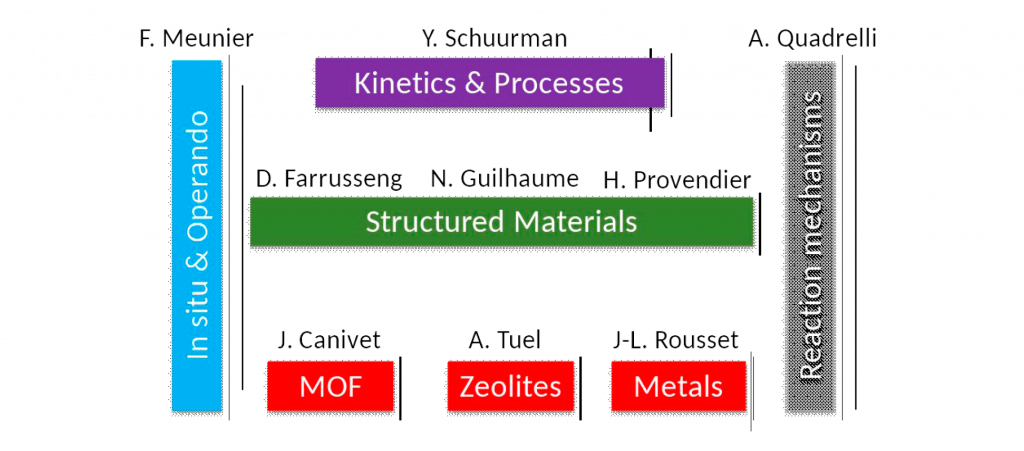

Area of expertise and contacts

- Waste and Biomass to fuel (Dr. Y. Schuurman)

- Catalysis for green energy and pollution remediation (Dr. N. Guilhaume)

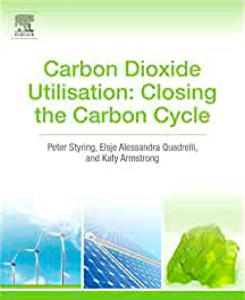

- Green chemistry and sustainable energy (Dr. Elsje Alessandra Quadrelli)

- Adsorption processes at solid interfaces (Dr. C. Daniel)

- MOF upscaling and energy storage (Dr. D. Farrusseng)

- Molecular catalytic materials (Dr. J. Canivet)

- New zeolites and inorganic supports (Dr. A. Tuel)

- Catalysis by metals (Dr. J-L. Rousset, Dr. F. Morfin)

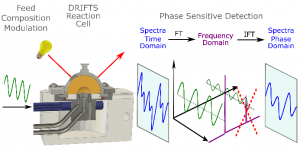

- In-situ & Operando studies (Dr. F. Meunier)

- Kinetic and transient studies (Dr. Y. Schuurman)

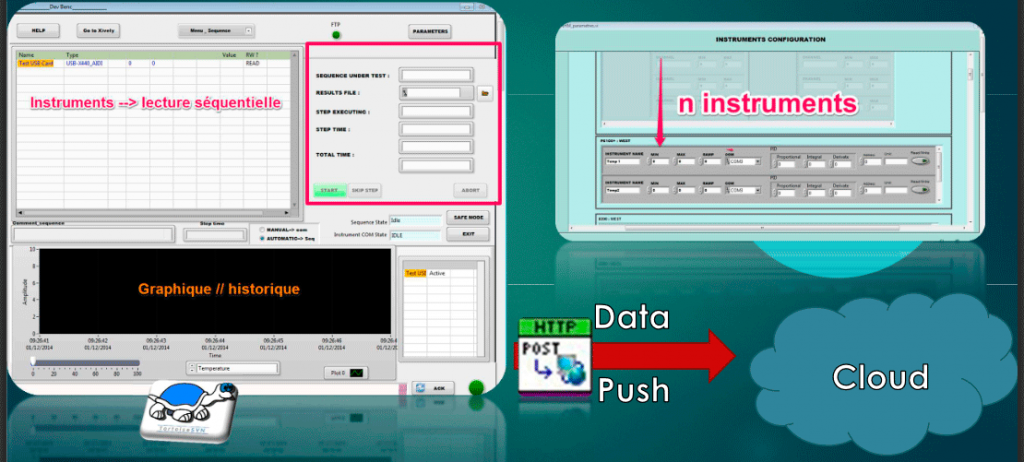

- Reactor automation & modular control (E. Landrivon)

|

Congratulations to David Farrusseng for the 2020 CNRS Silver Medal. |

|

Introduction

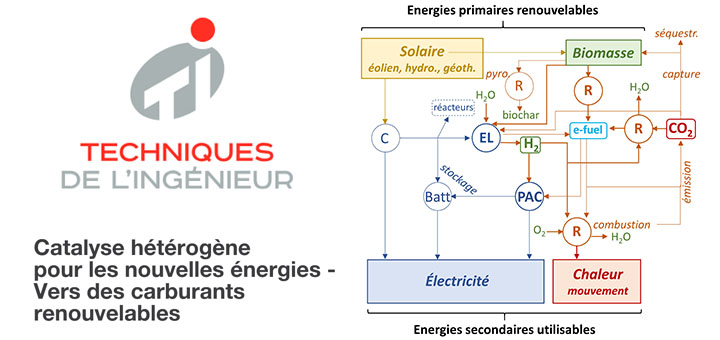

The intensification of sustainable clean, so-called green, catalytic processes is a crucial component of the actions aiming at tackling future energetic and environmental challenges. Process intensification requires the integration of novel step-change catalytic formulations used in newly designed reactors with improved energy savings, in part related to the steps involved in reactant purification and product separation.

Research areas

We look at different processes to convert wastes and biomass to gasoline. We study two main approaches of gasification and pyrolysis processes. For the gasification route, we investigate autothermal reforming reactor using structured catalysts. For the pyrolysis route, we study both bio-oil pyrolysis and its upgrading by FCC process thanks to specially designed test rig. A point of focus is the effect of feed composition and impurities on the activity, selectivity and poisoning of catalysts. |

|

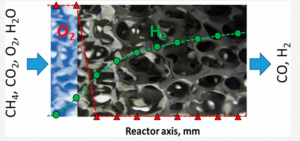

https://hydrogeneurope.eu/project/biorobur We study advanced and robust Biogas processing technologies for efficient hydrogen production. Our technology is based on a catalytic autothermal reforming route using easily-recoverable noble-metal catalysts supported on high-heat-conductivity cellular materials. This technology shows advantages compared to steam reforming: catalysts less prone to coking, easier adaptability to biogas changing composition, more compact design, efficient handling of heat, lower materials costs, fast start-up/shut-down, easier process control, etc. |

|

The conversion of CO2 into chemicals and fuels, with particular attention to industrial perspectives and large‐volume options. |

|

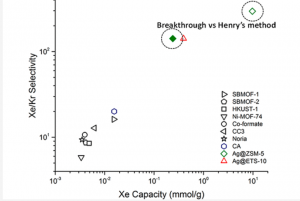

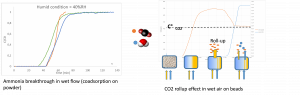

Although adsorption of reactants and desorption of products are two elementary steps of catalytic processes, the quantification of adsorption and diffusion rates on/in catalysts are usually overlooked. We can measure adsorption and diffusion in relevant conditions that provide key indications on catalyst or process design. In the context of innovation, our expertise has already led to the discovery and scale-up of successful adsorbents for atmospheric Xenon capture and air purification from ammonia, a Toxic Industrial Compounds (TIC) |

|

MOFs have been discovered about 20 years ago. Among the infinite possible structures, about a dozen of MOFs are commercially available at gram scale, but at a cost that prevent large scale R&D programs. We have entirely revisited synthesis processes and starting from cheap and available raw materials to achieve +100 kg/day scale production of high quality MOF, for example using spray-drying technology. We also study energy related applications, such as methane storage or chilling application using wasted heat. |

|

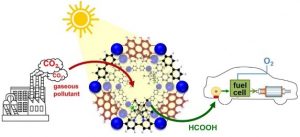

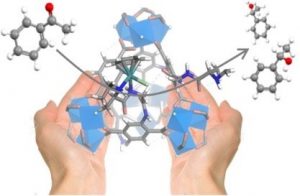

We are investigating new catalytic systems based on The Concept of Solid Porous Macroligands which address current challenges in fine chemicals synthesis and clean energy production by bridging homogeneous and heterogeneous catalysis using hybrid porous catalysts, especially Metal-Organic Frameworks (MOF). We also study novel purely organic porous platforms allows addressing new challenges in heterogeneous catalysis while tackling issues on stability and control over active site: Covalent Organic Frameworks (COF) and Conjugated Microporous Polymers (CMP). Applications range from C-C coupling to asymmetry, photocatalysis and solar fuels. |

|

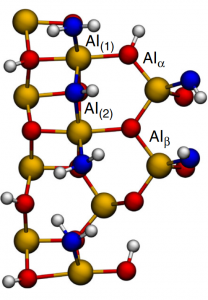

Synthetic zeolites are key catalysts for refinery and petro-chemical applications. We investigate original synthesis approaches to develop zeolites with unprecedent morphologies, such as hollow zeolites for encapsulation purposes and zeolites with high control of surface chemistry in order to tune their hydrophily-hydrophoby balance. |

|

Most of hydrogenation and oxidation processes are catalyzed by supported metal based catalysts, such as Pt/alumina or Pd/silica. Based on detailed surface chemistry studies, we investigate the reaction mechanisms, especially on the composition (alloy) and size effects of the metal particles (Single Atom Surface – SAC) and its interaction with the surface in line with the concept of Strong Metal Surface Interaction (SMSI) |

|

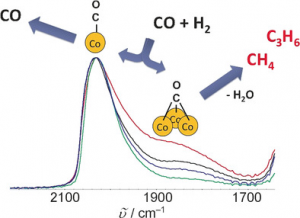

Catalyst active sites usually evolves at reaction conditions. This is particularly true for the surface of catalyst particles which often get restructured as their composition, oxidation state and morphology change with time on stream. By means of IR reactor cell, we study and characterize catalytic sites at work which allow to identify true catalytic sites and to establish structure activity relationships. |

|

|

|

Development of software and hardware solutions for control and monitoring of catalytic reactors |

|

Selected recently published examples

Model biogas reforming on Ni-Rh-Based catalysts. Autothermal reforming using Si-SiC Foam as support and effect of H2S and NH3 impurities

see Ind. Eng. Chem. Res. 2017 – doi 10.1021/acs.iecr.7b01559

and Chemical Engineering Journal 2020 – DOI: 10.1016/j.cej.2020.125534

Unravelling hollow sites as reaction intermediates in CO hydrogenation

see Angew. Chem. Int. Ed. 2018 DOI: 10.1002/anie.201710301

Multifunctional solids for photo/electrocatalysis and solar fuels

see ACS Catal. 2018, 8, 1653-1661 and Angew. Chem. Int. Ed. 2020, 13, 5116-5122

Bio-inspired solids for asymmetric catalysis

see J. Am. Chem. Soc. 2015, 137, 9409-9416 and Chem. Sci. 2020, 11, 8800-8808

Leading the field of Hollow zeolite single crystals and catalytic application

nearly 30 articles published by the team! Here is the state of the art and key articles:

Small Methods 2018 10.1002/smtd.201800197

ChemCatChem 2018 – 10.1002/cctc.201801225

Applied Catalysis A-General 2019 doi.org/10.1016/j.apcata.2018.10.028

Unravelling the kinetic stability of alumina in water

see Nature Communications volume 10, Article number: 3139 (2019)

Catalytic conversion of beech wood pyrolytic vapors

see Journal Of Analytical And Applied Pyrolysis 2018 – DOI: 10.1016/j.jaap.2018.01.015

Ag/ZSM-5 definitively the best Xenon adsorbent and by far!

see Ind. Eng. Chem. Res. 2019, – doi /10.1021/acs.iecr.8b04866

Research projects

Research strategy in the ING group mainly lies on EU collaborative research programs, French ANR projects and recurrent collaborations with national research centers and companies like IFPEN, CEA, St Gobain, Orano

On-going EU collaborative programs

- C123 : Methane oxidative conversion and hydroformylation to propylene (2019- 2023)

https://www.sintef.no/projectweb/c123/

https://www.linkedin.com/company/h2020-c123/

The H2020 funded C123 project aims at producing C3 products from methane available in stranded and natural gas. Here, we design and develop i) Oxidative coupling of methane Catalysts in presence of CO2 and ii) MOF and Porous Polymer’s catalysts for heterogeneous hydroformylation of ethylene at low pressure.

- IMPRESS: Integration of efficient downstreaM PRocessEs for Sugars and Sugar alcohols (2019- 2023)

https://www.spire2030.eu/impress

The EU-funded project IMPRESS develops a novel biorefinery concept, which allows the conversion of plant-based non-food materials into important base chemicals. The process involves the use of liquid chromatography purification technology, including a very efficient continuous separation technology. In this project, we design and develop nanoporous adsorbants (zeolites, MOFs) for the purification of light alcohols.

- H-CCATSolid catalysts for arylation of aromatic C-H bonds towards industrialization (2017- 2020)

The H-CCAT project devises solid hybrid materials that are superior catalysts for C-H activation on aromatic compounds, and develops innovative procedures to produce and shape these catalytic materials in an economically and environmentally beneficial way. The catalysts will allow sustainable production of pharmaceutically relevant compounds or other specialty chemicals. In this project, we design and develop organometallics@MOF as catalysts for C-H/C-X biaryls coupling.

- WASTE2ROAD – Biofuels from WASTE TO ROAD transport (2018-2022)

![]()

https://www.sintef.no/projectweb/waste2road/

https://www.linkedin.com/company/waste2road/

The objective of WASTE2ROAD is to develop a new generation of cost-effective biofuels from a range of low-cost biogenic residues and waste fractions (contaminated wood, black liquor from pulp and paper industry, and municipal solid organic waste incl. food residues).

- 4Refinery – Scenarios for integration of bio-liquids in existing REFINERY processes (2017-2021)

![]()

https://www.sintef.no/projectweb/4refinery/

4REFINERY develops and demonstrates the production of next generation biofuels from more efficient primary liquefaction routes integrated with upgraded downstream (hydro)refining processes to achieve overall carbon yields of >45%. Here, we investigate the effect of bio-oil addition on FCC performances.

- BIOROBURplus Advanced direct biogas fuel processor for robust and cost-effective decentralised hydrogen production

BioROBURplus builds upon the closing FCH JU BioROBUR project (direct biogas oxidative steam reformer) to develop an entire pre-commercial fuel processor delivering 50 Nm3/h (i.e. 107 kg/d) of 99.9% hydrogen from different biogas types (landfill gas, anaerobic digestion of organic wastes, anaerobic digestion of wastewater-treatment sludges) in a cost-effective manner.

On-going collaborative National funded programs

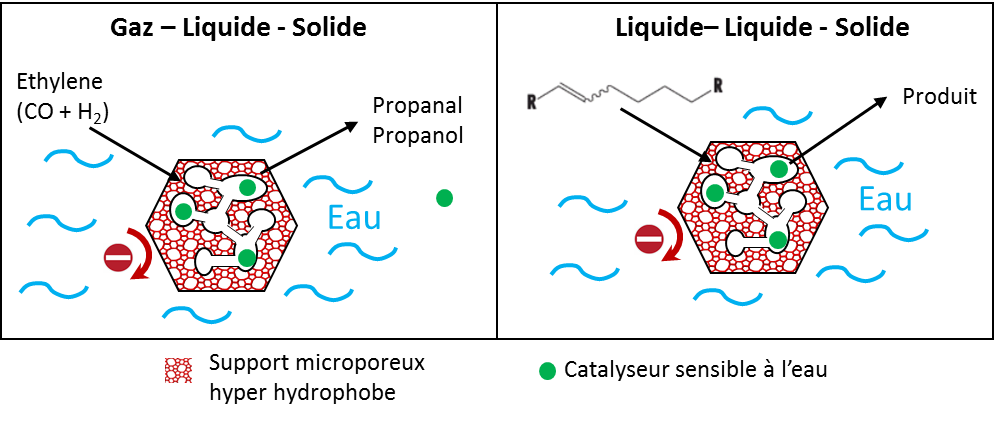

- CatCall Catalysis in water by super hydrophobe hollow shells as solid micelles (2019-2023)

https://anr.fr/Project-ANR-19-CE07-0025

https://www.linkedin.com/company/catcall-anr/

David Farrusseng coordinator “CATCALL deals with the discovery of selective and stable catalysts in water media without the use of noble metals. The project aims at the design of SOLID superhydrophobe catalysts in multiphasic processes. The role of the superhydrophobic catalyst support is to 1) prevent water to access to catalytic sites and 2) enable an overconcentration of substrates on catalytic sites in a kind of ‘Liquid with Permanent Porosity”. We are glad to collaborate with Dr. Benoit Coasne (CNRS – LiPhy).

- POMAC Porous materials for asymmetric catalysis (2018-2022)

https://anr.fr/Project-ANR-18-CE07-0025

https://www.linkedin.com/company/pomac-anr/

Dr. Jérôme Canivet, project coordinator “ We investigate ground breaking immobilization approaches for assymetric Catalysis. Our approach is based on Macroligand concept which brings the gap between molecular and solid catalyst”. We are glad to collaborate with Dr. Caroline Mellot-Drazniek (CNRS – Collège de France).

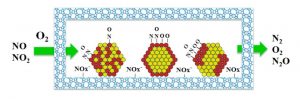

- DecompNOx – Nanoparticules multimétalliques à base d’or incorporées dans des nanoboites de zéolite pour la décomposition directe de NO en excès d’O2

https://anr.fr/Projet-ANR-18-CE07-0002

Dr. Frédéric Meunier, project coordinator “the project aims at developing new catalysts based on nanoparticles of alloy containing gold for the direct decomposition of NOx (2 NOx = N2 + x / 2 O2) in the presence of O2 without any reducing agent.” We are glad to collaborate with the Surface Reactivity Laboratory (LRS, Paris).

Partnerships

Current program

H-CCAT : https://cordis.europa.eu/project/rcn/206561_en.html

PRODIA : https://cordis.europa.eu/project/rcn/198807_en.html

C123 : https://cordis.europa.eu/project/rcn/198807_en.html

IMPRESS : https://www.avantium.com/renewable-chemistries/mekong/

Past

TOPCOMBI : https://cordis.europa.eu/project/rcn/75746_en.html

OCMOL : https://cordis.europa.eu/project/rcn/92879_en.html

NanoMOF : https://cordis.europa.eu/project/rcn/92877_en.html

FASTCARD : https://cordis.europa.eu/project/rcn/110686_en.html

Experimental and instrumental capabilities

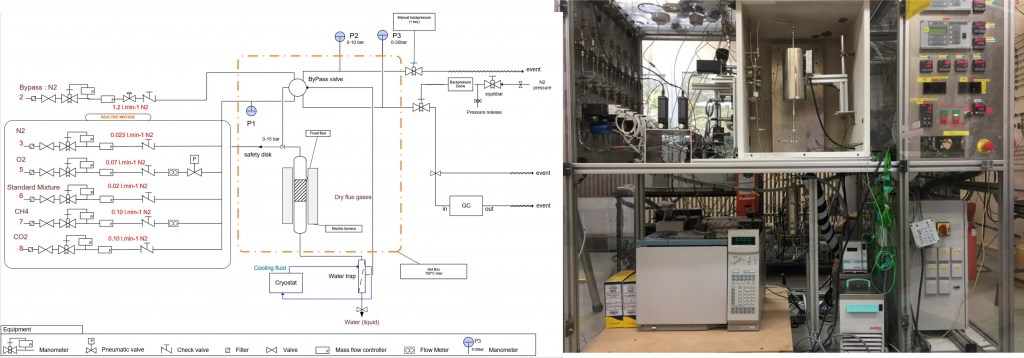

The ING team has an exceptional fleet of instruments dedicated to catalysis and adsorption designed and produced by the engineers and researchers of the team, including:

1- Custom-made catalytic test benches meeting application needs (C. Daniel, E. Landrivon, F. Morfin)

2- Platform for absorption and diffusion measurements (C. Daniel)

3- High-throughput heterogeneous catalysis platform (Management: C. Daniel, AxelOne Campus)

1- Custom-made catalytic test benches meeting application needs (C. Daniel, E. Landrivon, F. Morfin)

Our team designs and manufactures “tailor-made” catalytic test devices responding to various constraints such as pressure, temperature, residence time and reactor geometry. To design and produce these prototypes, the team relies on the skills of its staff in reactor sizing, process; instrumentation and sensors, analysis and automation. Security constraints are also taken into account thanks to servo-controlled sensor systems which allow equipment to be put in a fallback.

Examples:

- selective oxidation of methane at 800°C under 10 bars

- (oxy) vapor reforming of methane on foam type reactors

- Pyrolysis reactor

- MAT FCC reactor

- Conversion of CO2 to CSTR process

- Three-phase reactor for ethylene dimerization, hydroformylation

2- Platform for absorption and diffusion measurements (C. Daniel)

Static volumetric measurement: the team has 5 commercial measuring devices (Bel Japan).

- 2 Belsorp Mini for the characterization of porosity.

- 2 Belsorp Max for gas and vapor measurements (water, hydrocarbons, alcohols).

- 1 Belsorp HP for measurements of storage capacities in H2, CH4 and CO2.

The “ZLC” (Zero-Length Column) technique was implemented in to meet the needs of diffusion measurements, making it possible to establish the relationship between efficiency factor and Thiele’s modulus in hierarchical materials.

https://doi.org/10.1016/j.micromeso.2020.110499

Finally, to complete these two fundamental approaches to vacuum adsorption and ZLC, two pieces of equipment make it possible to perform dynamic drilling curves on demand. Different reactor sizes (powder, extrudes) as well as different probe molecule detectors (PID, FTIR) make it possible to test numerous configurations, in particular in co-adsorption. This close-to-the-process approach makes it possible to assess the capture / separation properties of materials designed by the team and / or shaped under real conditions.

Industrial & Engineering Chemistry Research 58 11 4560-4571 10.1021/acs.iecr.8b04866

Microporous And Mesoporous Materials 265 143-148 10.1016/j.micromeso.2018.02.011

3- High-throughput heterogeneous catalysis platform (Management: C. Daniel, AxelOne Campus)

Two Avantium Flowrence units are hosted on the Axel’One Campus collaborative platform. They allow the performance of catalysts to be established. Thanks to miniaturization and parallelization technologies, it is possible to test 16 catalysts per day under conditions close to those used in real applications and with unmatched quality.

These high flow units (EHD) have been set up with very strict HSE specifications (operate continuously 24 hours a day under pressure of CO and H2.)

The logistics and scientific management of the platform (collaborations, budget, maintenance of units, evolution of tools) is managed by IRCELYON (C. Daniel, D. Farrusseng).

Examples of studies using Flowrence units

- Kinetic study of Fischer-Tropsch catalysts: Catalysis Science & Technology, 2020, DOI: 10.1039/D0CY00918K

- Discovery of a non-linear trend in refining catalyst formulation: Chemcatchem, 2020, https://doi.org/10.1002/cctc.201902260

Staff

Researchers and University professors

Personnels techniques (en)

Postdoctoral fellows

PhD students

Interns

Publications

-

Rhenium‐Based Dual‐Function Materials for Integrated CO 2 Capture and Methanation

ChemCatChem, 2026, 18(1), pp. -

-

Organic-directed crystallization of Na-free Y zeolite with controlled framework composition

Microporous and Mesoporous Materials, 2026, 404, pp. 114045-114045

-

JOURNAL OF MATERIALS CHEMISTRY A, 2025, p.

-

Binary organosolv strategy for simultaneous high yield and structure preservation

GREEN CHEMISTRY, 2025, p.

-

Microwave-assisted oxidation of N2 to NO over perovskites

Applied Catalysis A General, 2025, 709, pp. 120661-120661